01.

Pulping

The virgin pulp bales are picked up from the warehouse and placed on loading belts and sent to the “pulpers” where the 100% virgin pulp is mixed with a lot of water to produce tissue-paper stock, which is sprayed onto screens of mesh to drain the water.

02.

Pressing & parent reel formation

The mixture is blown onto a screen, and then placed on felt, which carries it to an enormous cast iron or steel (Yankee) cylinder that is heated to 100° centigrade. Here, hoods blow hot air (450°) to dry the sheet, which is then rolled up to form the parent reel.

03.

Product specification control

The parent reels are checked to ensure that they comply with the main physical and technical parameters required for each type of use. Sample-based checks are carried out for other special requirements.

04.

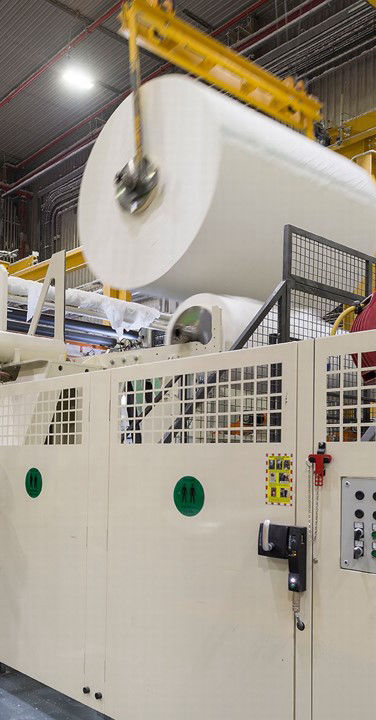

Rewinder multiple ply bonding

The parent reels start out as single ply paper. This machine bonds two, three or four plies depending on the specific needs of the product being made.

05.

Wrapping & Warehousing

The reels arriving from the re-winder are wrapped with a plastic film and labelled, then carried to the warehouse where they are stored until they are shipped to customers.